mechanical seals

1

ANSI Mechanical Seals

- Optimized for Extreme Conditions: Designed for high-pressure, high-temperature applications in the oil and gas industry.

- API 682 Conforming: Fully adheres to API design and qualification requirements.

- Unrivaled Bellows Tech: Welded in the USA.

2

API Mechanical Seals

- Optimized for Extreme Conditions: Designed for high-pressure, high-temperature applications in the oil and gas industry.

- API 682 Conforming: Fully adheres to API design and qualification requirements.

- Unrivaled Bellows Tech: Welded in the USA.

3

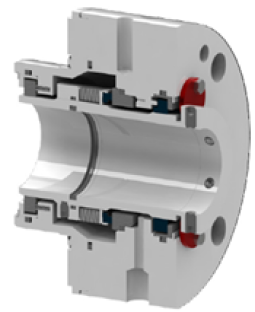

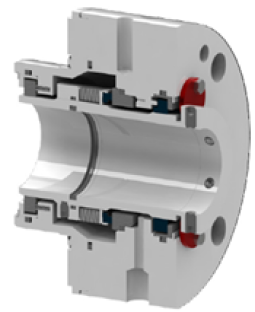

Split Cartridge Mechanical Seals

- Simplified Installation: Attaches in two pieces; easiest field-install in its class.

- Damage-Resistant Design: Secured faces in cartridge halves prevent damage.

- Pre-Tested Assurance: Factory-assembled and pressure-tested for guaranteed reliability.

- Style 86 Seal: Designed for versatility and ease of use across various rotating equipment.

4

Slurry Pump Seals

- Flushless single seal arrangement eliminates repacking and leakage headaches in slurries up to 60% solids.

- Built for the harshest slurry applications in mining, mineral processing, and any solids-handling processes.

- Double-seal configuration available with external seal support system for extreme services.

5

Component Seals

- Direct replacement seals for a full array of compressors, mixers, pumps, and other rotating equipment.

- Designed for a wide range of applications where cartridge seals are not practical.

- Fully stocked with a variety of single-spring, rotating bellows, and stationary seats (mating rings) for many common sizes.

6

Multi-Lip Cartridge Seal

- Solves the sealing problems associated with sticky, viscous, and hard-to-seal applications.

- Proprietary low-friction lip seals last longer in adverse services.

- Vibration and cavitation are well-tolerated compared to standard hard-faced mechanical seals.

7

Gland Packing System

- Shaft stabilization closer to your rotating element than ever before.

- Reduces water consumption up to 90% compared to standard packing arrangements.

- The bearing, working with die-formed packing rings, forms the most rugged gland packing system available.